|

Home

Going Lean in Health Care

Innovation in Organizations

Zero Defects

Eight Essential Tools for Six Sigma

Curious Cat Management Improvement Blog

Management Articles

Got Boondoggle? (lean)

Management Blog Directory

Panta Rei (lean)

Hexawise - software testing

Curious Cat Management Improvement Library

John Hunter

Management jobs

Leadership and Management Quotes

Public Sector Management Improvement

|

|

Quality Conversation with Gary Convis

Quality Conversation with Gary Convis by Norman Bodek: There are two pillars; one is continuous improvement. You might not call this a human issue exactly, but Toyota's success rests on the need for all employees, all management, to be looking for and striving for continuous improvement and never being satisfied. ... We believe very strongly in what the Japanese call " genchi genbutsu," the foundation of Toyota's engineering strategy, which means "Go, see, confirm and be aware with your own eyes." ... The other pillar of the Toyota way is respect for people and honesty. If you don't have respect for people who work for the company, you'’re in the wrong business. More lean thinking articlesPrevious posts on Toyota and TPS (lean)

Creativity Overflowing

Creativity Overflowing: It was clear that Whirlpool needed to reinvent its corporate culture. To do so, it had to figure out the answers to basic questions that managers everywhere struggle with: How do you define innovation? How do you measure success? How do you teach people to be creative? Related:

Using Design of Experiments as a Process Road Map

Using Design of Experiments as a Process Road Map by Davis Balestracci: The current design of experiments (DOE) renaissance seems to favor factorial designs and/or orthogonal arrays as a panacea. In my 25 years as a statistician, my clients have always found much more value in obtaining a process "road map" by generating the inherent response surface in a situation. It's hardly an advanced technique, but it leads to much more effective optimization and process control. DOE is a tool that is very useful. And while the situations in which DOE is the best tool to use is limited the limited use of DOE is used less than it could be. See more articles on the use of design of Experiments (DOE).

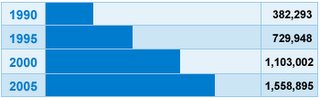

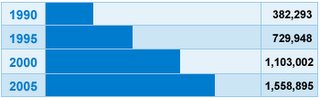

Toyota in the US Economy

Some figures on Toyota's economic impact in the USA. Toyota North American vehicle manufacturing totals:  From Toyota's web site: Toyota Manufacturing in the USA: by 2008, Toyota will have the annual capacity to build 1.81 million cars and trucks, 1.44 million engines, and 600,000 automatic transmissions in North America. The company's direct employment in North America is more than 38,000 and direct investment is nearly $16.8 billion with annual purchasing of parts, materials, goods and services from North American suppliers totaling an additional $26 billion. Toyota Touts Impact on U.S. in Billboards: The messages highlight numbers, such as 13 -- "Donuts in a baker's dozen; Toyota's U.S. investment, in billions," and 386,000 -- "Kilometers to the moon; U.S. jobs created by Toyota." The billboards are in some two dozen U.S. markets where Toyota has factories or supplier operations, from Fremont, Calif., where Toyota partners with GM at an automaking plant, to Huntsville, Ala., where Toyota makes engines.

The World's Most Innovative Companies

The World's Most Innovative Companies: Today, innovation is about much more than new products. It is about reinventing business processes and building entirely new markets that meet untapped customer needs. Most important, as the Internet and globalization widen the pool of new ideas, it's about selecting and executing the right ideas and bringing them to market in record time.

...

Consumers increasingly are doing the innovation themselves. Consider Google Inc. (GOOG ), our No. 2 innovator, and its mapping technology, which it opened to the public. This produced a myriad of "mash-ups" in which programmers combine Google's maps with anything from real estate listings to local poker game sites.

Google's mash-ups are just one example of the escalating phenomenon of open innovation. These days the world is your R&D lab. Customers are co-opting technology and morphing products into their own inventions.

Leading Lean: Missed Opportunity

Leading Lean: Missed Opportunity by Jamie Flinchbaugh: Three elements are needed to gain the benefits from using pull production to drive problems out into the open. First, you need strong problem-solving skills. Bringing a problem to the surface is only half of the battle-you still have to correct the problem. Second, you need an infrastructure capable of solving problems. This means persuading employees at all levels to respond to problems in real time. This does not happen overnight. Third, and perhaps most important, you need a culture that values solving problems as prevention, not crisis management, and is willing to step up even if the problems seem small at the moment. Great points. One of the counter intuitive things with lean is to make problems visible. So often people try to hide problems (which inventory can do - making it difficult to see emerging problems and to diagnois problems once they are finaly discoverd). The idea that you then must improve the system as these problems are made visible is fairly obvious but is also worth emphasising since without it the problems increase. I think the typical perfromance appraisal process adds to the desire to hide problems. As does excess mobility of management (just hide it until you move on). These show my Deming view of management leanings.

Via the lean blog.

The Art of Customer Service

The Art of Customer Service by Guy Kawasaki: 4. Don't point the finger.

This is the flip side of taking responsibility. As computer owners we all know that when a program doesn't work, vendors often resort to finger pointing: "It's Apple's system software." "It's Microsoft's 'special' way of doing things." "It's the way Adobe created PDF." A great customer service company doesn't point the finger--it figures out what the solution is regardless of whose fault the problem is and makes the customer happy. As my mother used to say, "You're either part of the problem or part of the solution." (By the way, as a rule of thumb, the company with the largest market capitalization is the one at fault.)

Toyota Again Get Positive Press

Toyota Eyes Chance to Pass by Anthony Faiola, Washington Post: The mainstream press continues to note the success of Toyota. Toyota has been toying with hybrid engines for the past 20 years. But the company began to seriously pursue a mass-producible hybrid in 1993. Ogiso, 45 years old and now the chief engineer on the third-generation Prius still under development, said the edict came from Eiji Toyoda, the patriarch of the Toyota family who headed the company until 1994.

Ogiso said Toyoda had grown increasingly concerned that gas-engine auto manufacturing would eventually become a sunset industry given the limits of global oil supplies and increasing pressure to curb emissions. Focused more on a long-term advantage than the short-term gains that U.S. automakers are under pressure from Wall Street to produce, Toyota put hundreds of engineers to work on creating a new engine that would double average gas mileage and cut emissions by 80 percent. Conventional engines were quickly ruled out. "We found that the only way to achieve that goal was building a whole new type of car," Ogiso said. This shows several of Deming's ideas which are part of the Toyota Production System (lean manufacturing) most importantly: constancy of purpose. Several of the seven deadly diseases are also seen in the collapse of GM, such as: emphasis on short term profits, mobility of top management and excessive medical costs. The relentless push for efficiency often takes shape in small ways. Two years ago, the company came up with a new process in which parts for specific models were presorted into blue boxes that travel down the line as each car is assembled. Though low-tech and inexpensive to put into effect, it significantly sped up the product line and saved space by doing away with the need for workers to seek out different auto parts from storage bins. It was one of roughly 600,000 small improvements Toyota makes annually. Toyota continue to execute on many fronts continual improvement, innovation and strategic planning. Related posts:

Seduce Them With Six Sigma Success

Seduce Them With Success by Jay Arthur: Instead the change agents are going around talking to operational managers, learning their problems and offering to help solve them. Then, using the tools of Six Sigma, they find remarkable, unexpected solutions that reduce costs and increase speed and profitability. Oddly enough, the people on those improvement teams seem to know how to continue solving problems. And they tell their co-workers. And the operational manager's success makes his or her colleagues curious. Then the Six Sigma change agent gets a call to help another manager solve a problem. And so it goes until the Six Sigma system is operating well in the mission-critical elements of the business. This is the way to get management improvement to take hold. Use successes to create a desire to improve. It is always nice if the leaders are on board, it helps in many ways. But whether they are or not, those seeking to promote management improvement need to pay close attention to how much desire exists to improve (using six sigma or lean or process improvement or quality management tools). If most people think the efforts are just the latest fad it is very difficult to have any lasting success. More six sigma articles.

Lean Thinking Needed

Bank Wire Transfers vs. FedEx DeliveryMy goal was to give them all the paperwork, ensure I had sufficient funds, and schedule the transfer such that the money arrives in the sellers' account on a particular date next week.

But they can't do that. They cannot hold the paperwork for any amount of time. They'll process it the same day I turn it in. I guess I can understand that. They're a bank, not a scheduling service.

However, they can't tell me which day to drop of the paperwork to ensure that the funds arrive on my target date. The teller informed me that "it usually takes 48 hours, but that doesn't mean the funds will be available on the other end."

...

I can get a FedEx envelope, stuff it with $100 bills (or a certified bank check), and send it overnight with a signature required for less than $30 (without insurance). In this scenario, I get to track the progress of my package remotely and am fairly certain that it will arrive on the right day.

It seems to me that FedEx is better at what ought to be a core competency of an organization like Bank of America. It seems to me a bank that can't do better than this should be embarrassed. They need read management improvement articles or Lean Solutions and start delivering decent service or let someone else manage the company.

Lean Manufacturing Success

Oshkosh Truck Driven to Succeed by Arlen Boardman: Wuest said this reduced the order-to-delivery time from 12 to 16 weeks to seven days. It made better use of manufacturing space and reduced inventory-holding costs. He said it does many more things, like create an orderly work area, so tools are where they're supposed to be, and parts are made when needed, one at a time.

"The goal is to turn an order into cash as quickly as you can," he said.

Specialists in lean manufacturing systems were hired to help at Oshkosh Truck, including ones from General Motors and Ford Motor, among other big-name companies. This specialized team instills a belief in the changes and then conducts the training for the workers. Not only is this a nice story but it is one small example of the good people working at GM and Ford. The problem is not the individual workers it is management. It is too bad that those companies, that did take great strides in the 1980 and early 1990s to improve (starting with Deming's Management ideas) let those efforts fade away. I followed the link from, Some Positive Lean Tales, wrote the above and then went back to continue reading Mark Graban's post, which stated: I guess this proves there are no shortage of good lean people at GM and Ford (I learned from some great lean people back at GM), but they're constrained by the system that they're a part of. We seem to be thinking the same way on this one. Another link from his post, Going Lean by Paul Marks: "It's imperative for those companies that can implement lean manufacturing to do it," Johnson said. "The only way companies in Connecticut can compete, with the high cost of doing business here, is through productivity gains. The objective is to put more pieces out the door than you did last year, and do it with the same number of employees."

Because "set-up" time when a machine takes on a new task halts the entire production line, Whitcraft has found ways to ease the transition.

Making all dies used on a punch press the same height eliminated the need to recalibrate and then test the machine before resuming work, Paul said. A transition that once took 45 minutes to an hour now requires about three minutes, he said. Workers are trained to think in those terms.

US Manufacturing Plant Construction

Topic: economics, manufacturingBreaking Ground by Jeff Moad: Last year, according to figures from the U.S. Department of Commerce, investment in new manufacturing plant construction increased 25%. That compares to a decline of 6.5% in 2003 and an increase in 2004 of 9.7% As we have noted earlier, the United States is by far the leading manufacturer in the world: Global Manufacturing Data by Country and Manufacturing and the Economy (Japan is second and China third and growing rapidly). The mini-revival in new-plant development has been enough to slow what until recently had been a prolonged decline in the number of manufacturing plants operating in the U.S. Between 1997 and 2004, according to the U.S. Department of Labor (DOL), the number of plants operating in the U.S. dropped by 10%. In 2005, however, according to DOL figures, the number of plants stabilized at around 336,000. Even though the US manufacturing output has continued to increase those gains have come largely from improved efficiency as fewer workers (and fewer plants) are producing the increased output. The decrease in employment is a worldwide phenomonon: Manufacturing Job Losses: USA 2 million, China 15 million.

|